End Application

HDPE coextruded capstock decking

Leading Composite Decking Brand Supplying Major Retail

Channels

Coextruded HDPE capstock decking

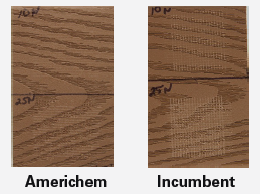

A major composite decking manufacturer aimed to compete directly with premium brands sold through national retailers. To do that, they needed a product with high-end aesthetics, strong durability, and reliable production consistency. The specific surface requirements created a unique challenge. The material had to deliver a low-gloss appearance, deep-grain embossing, and measurable scratch and mar resistance. Existing materials could not deliver all three without compromise. Gloss varied with embossing depth, durability was inconsistent, and color varied from run to run. In-house testing methods were also limited, making it difficult for the customer to validate surface performance or maintain visual standards.

Americhem supported the customer with two distinct solutions across separate product lines: a custom precolored HDPE compound designed for deep embossing and low-gloss durability, and a custom masterbatch developed to ensure consistent color across a second HDPE capstock product. Both offerings met different application needs, but together reflect Americhem’s full-spectrum capability in supporting performance and visual consistency across composite decking systems—reinforced by comparative data demonstrating superior scratch and mar resistance in each application. The project also required hands-on collaboration. Americhem provided field and on-site technical support, helping the customer’s team:

This combination of formulation and training helped align production teams, improve internal testing, and accelerate product development.

Americhem’s dual offering of engineered compounds and masterbatch technology was only part of the solution. What made the difference was the guidance provided throughout development. By helping the customer implement repeatable evaluation methods, Americhem reduced guesswork and helped build internal confidence. The team could now validate surface performance, make faster material decisions, and maintain higher consistency across SKUs.

The decking product launched with a scratch-resistant, low-gloss surface that matched the aesthetic of top-tier brands. Color was consistent across runs, and the texture remained sharp even under heavy embossing. Internally, the customer adopted new testing tools and evaluation protocols, which reduced delays and improved decision-making. This collaboration helped the customer launch a better product and strengthen their overall product development process.

Download the complete case study as a PDF for detailed insights, data, and results you can share with your team.

HDPE coextruded capstock decking

Composite decking OEM, Big Box channel

Precolor HDPE compound and custom masterbatch

Scratch/mar resistance, gloss control, weatherability, compatibility with deep embossing

Color consistency, visual evaluation support, scratch and mar test method training

220-550 lbs.

Material development, field support, technical training

Improved surface durability, consistent visual quality, validated internal testing