Friction Reduction

Minimize noise and vibration in moving plastic parts.

Built to minimize friction from the inside out, these internally lubricated compounds extend product life and eliminate the need for external greasing, making them a lightweight, corrosion-resistant alternative to metal in demanding plastic applications.

Whether you’re designing surgical devices, automotive components, or building materials, InLube™ delivers application-specific wear resistance and self-lubrication, engineered to match your performance, weight, and processing targets.

Engineered for motion, InLube™ compounds deliver smooth operation and long-lasting durability in demanding applications.

InLube™ internally lubricated compounds reduce friction, noise, and wear in moving plastic parts. These high-performance materials offer a lightweight, corrosion-resistant alternative to metal, ideal for demanding applications. With customizable formulations and over 30 base resins, InLube™ enhances durability and extends product life across industries.

Minimize noise and vibration in moving plastic parts.

Internally lubricated materials reduce wear and prolong durability.

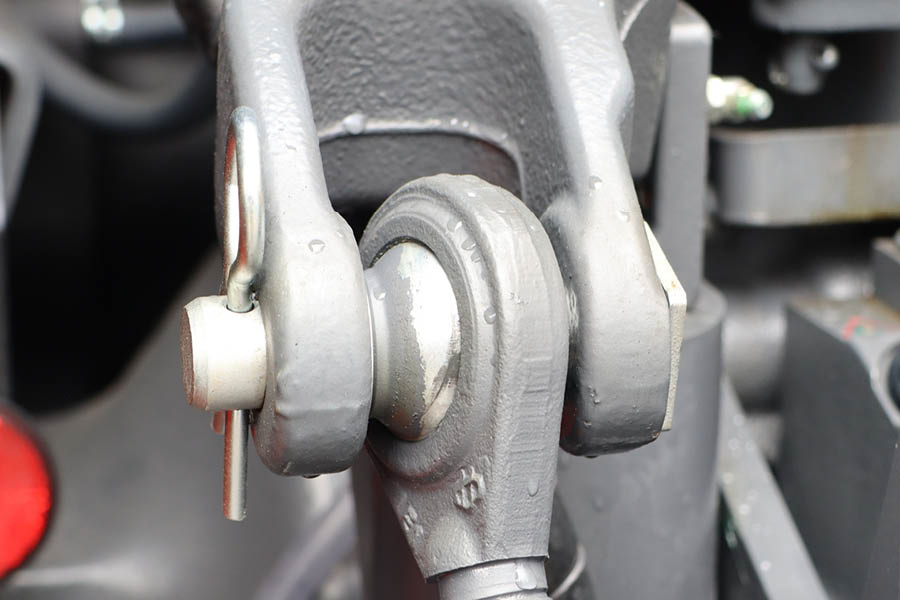

Lightweight, corrosion-resistant alternative to metal components.

Tailored with reinforcements and additives for specific applications.

Ideal for medical devices, automotive parts, and building materials.

We engineer InLube™ compounds to deliver long-lasting lubrication, reduce friction, and enhance performance across demanding applications.