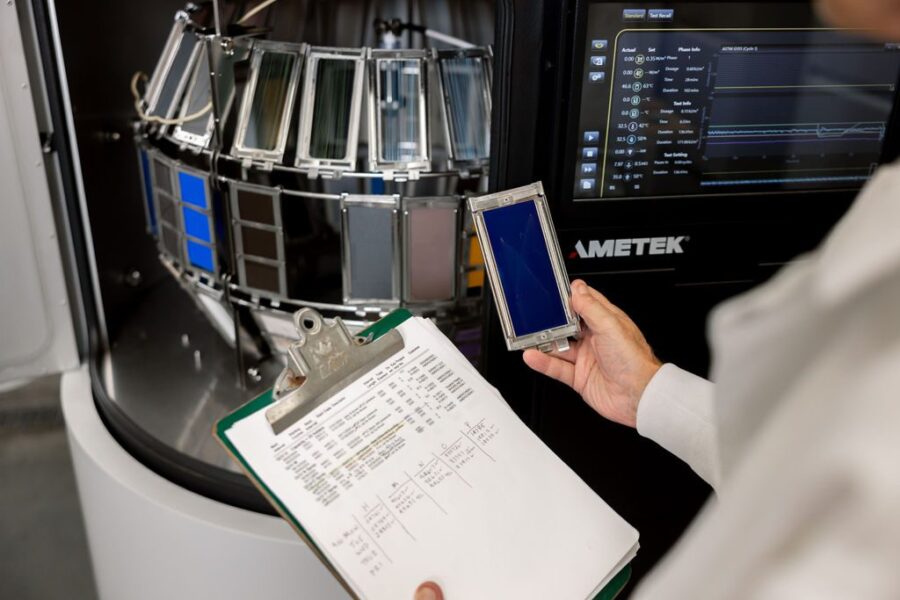

UV Resistance & Color Fade Testing

We assess how your materials hold up under UV exposure using QUV and xenon arc testing, measuring gloss retention, discoloration, and surface degradation.

Whether you’re developing a new compound, evaluating competitive materials, or troubleshooting production issues, our advanced analytical testing helps you make informed decisions backed by science.

We customize every test protocol to your specific materials, end-use environment, and compliance requirements, so you get answers, not just data.

UV, moisture, and heat can break down even the best materials. Americhem’s weathering testing services simulate real-world conditions so you can validate durability, reduce product failure, and extend lifecycle performance.

We assess how your materials hold up under UV exposure using QUV and xenon arc testing, measuring gloss retention, discoloration, and surface degradation.

Simulate rain, condensation, and heat cycles with precision-controlled chambers to evaluate swelling, warping, cracking, and delamination risks.

From visual inspection to mechanical property testing post-exposure, we ensure your parts retain performance and appearance over time.

Americhem’s testing protocols are aligned to ISO, ASTM, SAE, and OEM-specific standards so you can validate your products for international markets and regulated industries.

Strength, stiffness, and impact resistance aren’t just specs. They’re essential to your product’s success. Americhem’s physical property testing services validate how your materials behave under stress, strain, and load in real-world applications.

We measure how your materials stretch, bend, and hold their shape under load, providing key data on strength, elasticity, and deformation.

From Izod to Charpy, our impact testing evaluates how well your materials absorb energy under sudden stress or collision conditions.

Test for material surface hardness, compression strength, and load-bearing capacity to ensure durability in high-pressure applications.

Thermal performance can make or break a material in real world use. Americhem’s thermal property analysis evaluates how your polymers respond to heat, ensuring your products withstand the temperature demands of your application.

Measure glass transition, melting temperature, and crystallinity to evaluate material thermal transitions under controlled conditions.

Determine thermal stability, degradation temperature, and compositional analysis by measuring weight changes during controlled heating.

Test your material’s resistance to deformation under load at elevated temperatures which is critical for high-heat applications.

Analyze how your materials expand or transfer heat under temperature variation, a key to dimensional stability and thermal management.

Analytical testing is more than a lab service, it’s part of Americhem’s end-to-end support model. Our team of experts works with yours to interpret results, recommend improvements, and turn insight into action.