- Products & Materials

-

-

-

Product Families

-

-

-

-

Products & Materials

We collaborate closely with your team to deliver application-specific plastic compounds and accelerate your time to market.

-

-

- Industries

-

-

Solutions for Your Industry

We work with manufacturers in high-stakes industries like healthcare, automotive, electronics and building materials where performance, compliance and reliability are essential.

-

- Building & ConstructionMaterials that withstand weather, UV, and structural demands in outdoor and load-bearing applications.

- TransportationEngineered compounds built for durability, compliance, and reliability across vehicles, aircraft, ag, and power sports.

- FibersSoftness, strength, and stability for nonwovens, synthetic turf, hygiene products, and performance textiles.

-

- PackagingCustom masterbatches and additives for barrier performance, clarity, and sustainable packaging formats.

- HealthcareMedical-grade materials engineered for biocompatibility, sterilization, and global regulatory compliance.

- ElectronicsFlame-retardant, antistatic, and heat-resistant compounds for electronic housings and sensitive components.

-

-

- Services & Expertise

-

-

Services & Expertise

Americhem isn’t just a compounder, we are a full-service extension of your engineering, marketing, and product development teams.

-

-

- About

-

-

About Americhem

For more than eight decades, Americham has been your trusted global partner in designing and manufacturing polymer solutions.

-

-

- Talk to an Expert

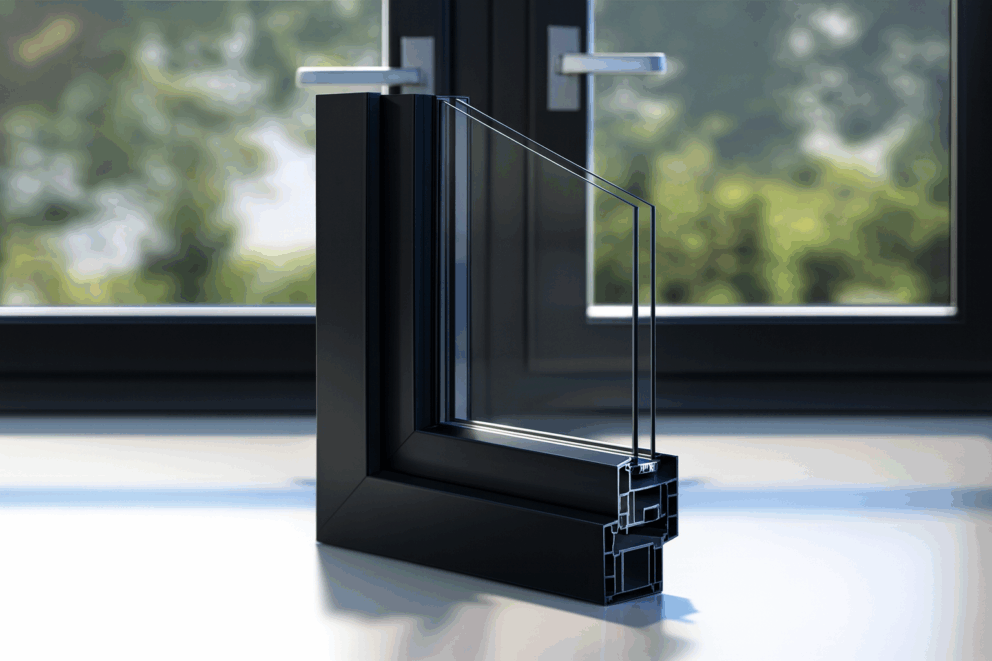

Rethinking Window Systems: A Case for Polymer Material Alignment

Industries:

Building & Construction

Topics:

ApplicationsEngineered CompoundsMasterbatchSustainabilityWeatheringWindows

Modern window system design increasingly calls for thinner profiles, darker colors, and performance under more demanding loads and climates. These trends are driving OEMs to reevaluate how materials are specified, sourced, and integrated across visible and hidden components alike.

When multiple suppliers contribute to a single system – color masterbatch from one vendor, profile compound from another, and motion part resins from a third – it introduces potential for failure at the interface level. Differing thermal expansion rates, inconsistent processing behaviors, or even color mismatches can slow validation cycles or drive up scrap.

OEMs can reduce that risk by partnering with a materials supplier that supports the polymer-based components of the window system. With engineered thermoplastics and pre-colored compounds, Americhem provides material alignment across form, function, and finish.

Solving for System Misalignment in Window and Door Material Solutions

Disparate materials often behave unpredictably when assembled under stress. For instance, dark window frames exposed to sun can experience differential heat gain, especially when carbon black-filled PVC interacts with metal reinforcement or adjacent plastics. This mismatch increases the risk of warping, fastener stress, or surface whitening.

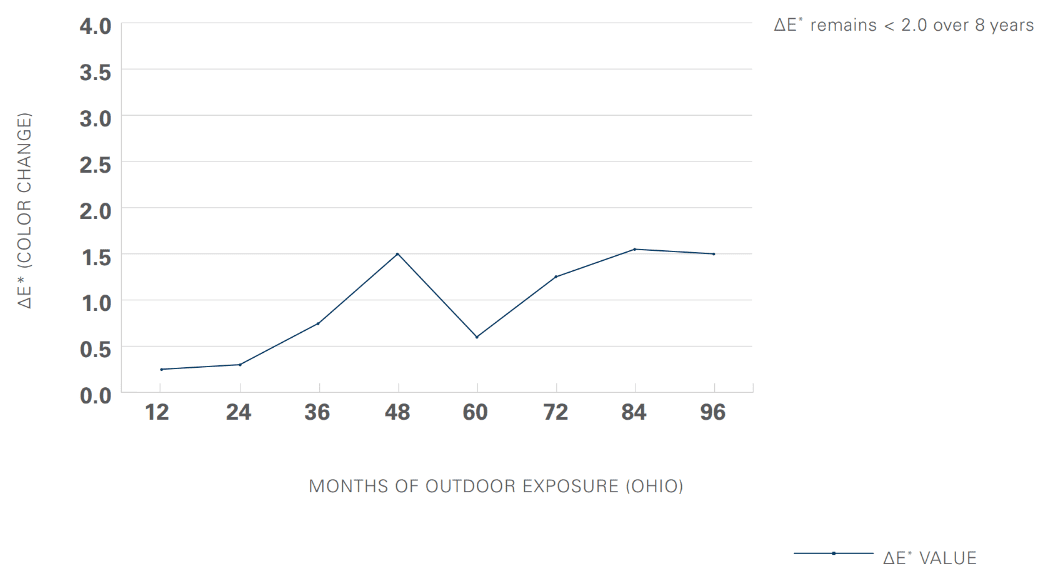

Materials like eCap™ ePVC help manage this variability. In natural exposure testing, these formulations showed significantly lower color change (ΔE) over 24 months compared to black PVC, while also resisting gloss loss and moisture whitening. In LHB test data, ePVC delivered up to 9.2°C lower surface temperature than conventional dark systems.

Addressing Structural and Motion Challenges with Engineered Thermoplastics

As OEMs seek to simplify part counts and slim profile walls, structural and motion-related materials must meet tighter tolerances without sacrificing durability. That includes everything from screw bosses and reinforcement chambers to tilt shoes and rollers.

Americhem’s portfolio includes solutions validated through ASTM D3702 testing and field use in regulated environments where long-term performance matters. Some options are PFAS-free and non-migratory, helping address evolving regulatory and sustainability goals.

For high-load or tight-tolerance zones, reinforced thermoplastics with mineral, glass, or carbon fillers provide strength and creep resistance. Other materials incorporate lubrication directly into the resin to reduce friction, die buildup, and scrap without affecting surface finish or tool life.

Full-System Material Development for Window OEMs

Americhem’s value is not just in breadth of materials, but in the alignment between them. Color and compound are developed under the same roof, enabling better coextrusion behavior, cleaner weld lines, and repeatable aesthetics across assemblies. Formulations can be customized to meet application-specific goals around appearance, durability, and processing.

OEMs also have access to weathering simulation, stress testing, and coextrusion trials to support ASTM and AAMA validation and reduce development cycle time.

For design teams exploring alternatives to multi-vendor strategies, this integrated approach offers a clear path to performance alignment.

Next Steps: Aligning Materials Around OEM Objectives

If your team is reassessing materials for an upcoming window platform, Americhem can provide a system review across structural, aesthetic, and motion components. Request a consultation or sample set tailored to your priorities.

Explore alignment across your window system from exterior to core, with proven compounds that support durability, regulatory compliance, and processing consistency.

Americhem’s Full-System Material Platforms for Window Applications

eCap™ Pre-Colored CompoundsFormulated for window profiles and capstocks, eCap™ improves long-term weatherability, color retention, and scratch resistance in outdoor environments. Ideal for exterior frames, it supports dark color aesthetics without moisture whitening and is compatible with woodgrain effects. |

EcoLube™ PFAS-FREE InternalLY LubricaTED COMPOUNDSPFAS-free compounds for high-motion window components like rollers, pivot locks, and tilt shoes. Engineered to reduce friction, wear, and noise without external greasing. Proven in ASTM D3702 testing to extend part life under dynamic loads. |

InLube™ INTERNALLY LUBRICATED CompoundsBuilt-in lubrication to improve processability during extrusion or molding. Suitable for tight-tolerance window hardware and moving assemblies, reducing buildup and extending tooling life while maintaining surface quality. |

InStruc® Structurally Reinforced CompoundsHigh-stiffness compounds designed for structural reinforcements, screw bosses, and load-bearing areas inside window frames. Reinforced with mineral, glass, or carbon fillers and available across 30+ base resins to support lightweight design and long-term dimensional control. |

Americhem’s compounds are fully customizable to align with your specific design, processing, and performance targets. Ask us how these platforms can support your next complete window system.

Talk to a Materials Specialist