Custom Color Masterbatches

We provide custom color masterbatch solutions to ensure optimal color design, reliable quality, and enhanced compatibility across diverse polymer types.

Our masterbatch solutions address complex product and processing challenges with precision and reliability.

For your specific applications, processes and compatibility needs, you can rely on Americhem’s masterbatch technology and compounding services for:

Get the color and additive concentrates that help you meet your specifications, achieve compliance and move faster from concept to production. Each formulation is built for consistency, precision and performance in high-stakes applications where there’s no room for error.

We provide custom color masterbatch solutions to ensure optimal color design, reliable quality, and enhanced compatibility across diverse polymer types.

Whether you’re looking for a realistic woodgrain, an impressive metallic effect or a pearlescent shine, we offer compatible colorants and functional masterbatch solutions that are customizable for a variety of resins and more.

Leverage our polymer additive masterbatch expertise to ensure seamless integration, optimal dispersion and consistent processing.

We offer a range of color and additive masterbatches designed to meet appearance, performance and processing needs across industries.

Each is formulated to perform reliably in real-world manufacturing environments, with high-quality dispersion and consistent color harmony between materials.

Since 1941, Americhem has grown into one of the world’s largest custom color masterbatch manufacturers. We work closely with top material suppliers to deliver reliable color concentrates, high pigment loading and proven additive solutions.

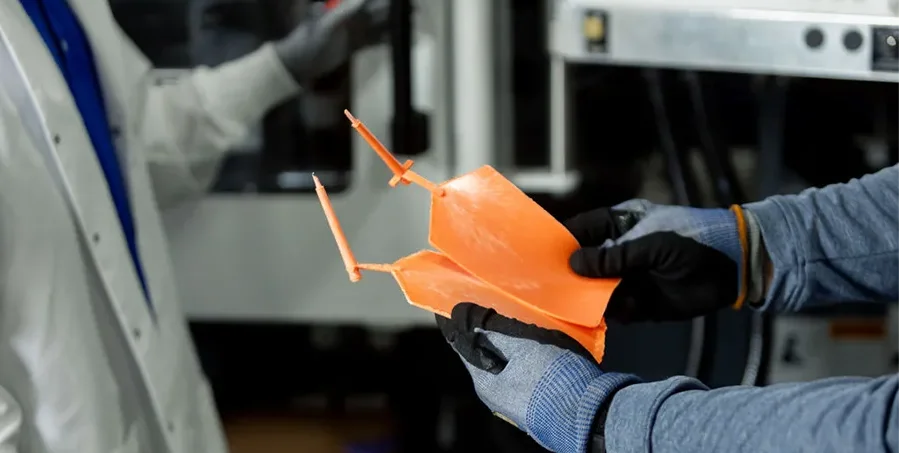

It is a solid additive used to color or impart other properties, such as texture, to plastics during the manufacturing process. The former are called color masterbatches while the latter are known as additive masterbatches. Depending on the application, masterbatches can come in a variety of forms including liquids, granules, mini beads and powders.

The process of producing color masterbatches can drastically change depending on the specific applications and needs of a customer. In general, the production of color masterbatches follows the process of (1) identifying and weighing pigments and additives, (2) mixing these pigments and additives into a carrier resin or polymer by heat treatment and typically twin screw extruding and (3) cooling and forming the concentrated mixture into granules, powder, and other color masterbatch vehicles.

Masterbatches are added or “let down” into the raw polymer or materials and go through a blending process commonly in a bucket or tumbler which feeds into a molding or extruding machine where the final plastic product is made. Americhem’s additive and color masterbatches are customized to the specific industry and application to ensure this manufacturing process goes smoothly and produces a high-quality product without defects or imperfections.

We can help you find the right formulation, troubleshoot a processing issue, or explain how our additives work in your application.