- Products & Materials

-

-

-

Product Families

-

-

-

-

Products & Materials

We collaborate closely with your team to deliver application-specific plastic compounds and accelerate your time to market.

-

-

- Industries

-

-

Solutions for Your Industry

We work with manufacturers in high-stakes industries like healthcare, automotive, electronics and building materials where performance, compliance and reliability are essential.

-

- Building & ConstructionMaterials that withstand weather, UV, and structural demands in outdoor and load-bearing applications.

- TransportationEngineered compounds built for durability, compliance, and reliability across vehicles, aircraft, ag, and power sports.

- FibersSoftness, strength, and stability for nonwovens, synthetic turf, hygiene products, and performance textiles.

-

- PackagingCustom masterbatches and additives for barrier performance, clarity, and sustainable packaging formats.

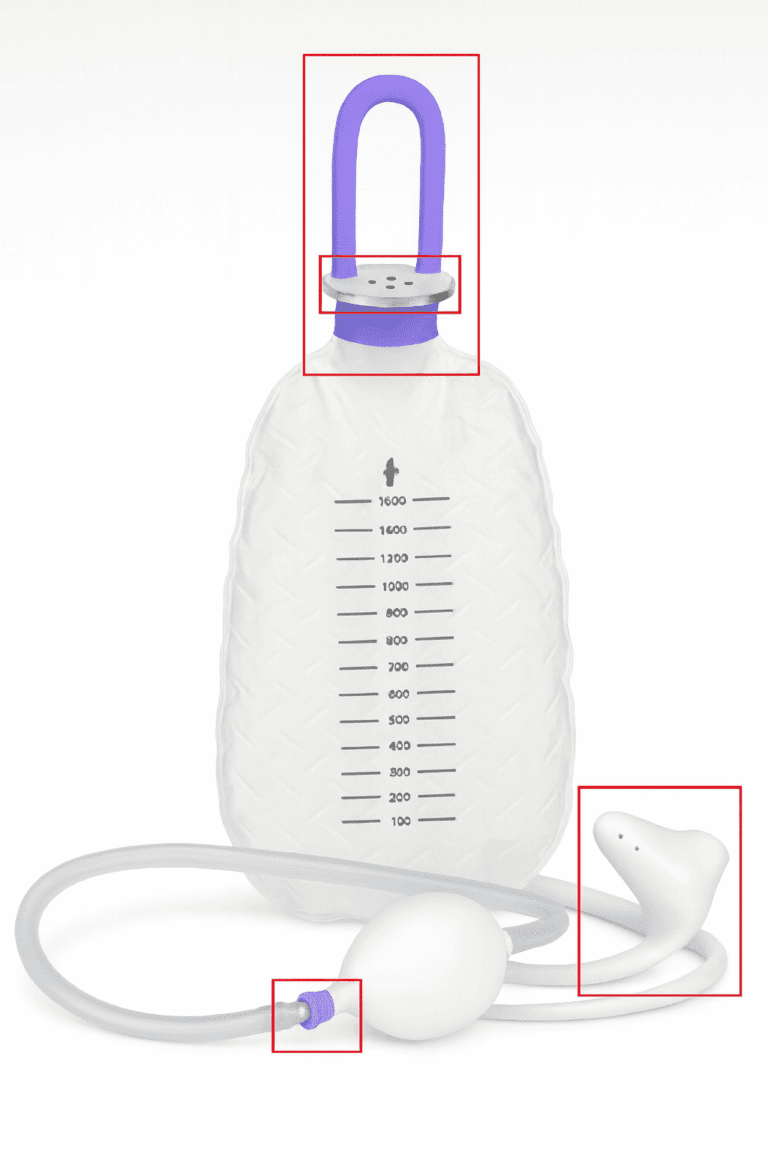

- HealthcareMedical-grade materials engineered for biocompatibility, sterilization, and global regulatory compliance.

- ElectronicsFlame-retardant, antistatic, and heat-resistant compounds for electronic housings and sensitive components.

-

-

- Services & Expertise

-

-

Services & Expertise

Americhem isn’t just a compounder, we are a full-service extension of your engineering, marketing, and product development teams.

-

-

- About

-

-

About Americhem

For more than eight decades, Americham has been your trusted global partner in designing and manufacturing polymer solutions.

-

-

- Talk to an Expert

Solve Tough Design and Manufacturing Challenges with Custom Compounds

Americhem’s engineered thermoplastics balance appearance, strength, and processability—backed by decades of application-driven R&D.

Every Americhem compound starts with a performance goal and is reverse-engineered to meet it. We select from over 30 base resins—like PC, TPE, TPU, PBT, and PEEK—and enhance them with custom additive and filler packages to deliver:

- Structural durability for load-bearing parts

- Visual and tactile quality for consumer-facing components

- Regulatory compliance: ISO, RoHS, REACH, FDA

- Processing efficiency for extrusion, injection molding, or blow molding

- Proven performance backed by 75+ years and the LTL Color Compounders legacy

Formulations are available in pre-colored, additive-integrated, or unfilled formats to match your goals.

Built to Perform Where It Matters Most

Whether your challenge is mechanical strength, aesthetics, or regulatory compliance, our compounds are engineered to meet it.

Americhem’s custom thermoplastic compounding blends resin science with end-use insight. Our team works with OEMs across aerospace, automotive, medical, consumer, and building sectors—so we know the risks, regulations, and performance thresholds your parts need to meet.

Choose the Right Engineered Compound for Your Application

Each compound line is engineered to solve real-world design, production, or compliance challenges.

Common Questions About Custom-Engineered Compounds

Get clarity on specs, compliance, and what makes Americhem’s engineered polymers different.

Still have questions?

Every compound starts with a carefully selected base polymer, chosen from over 30 resin types. We integrate colorants, additives, and reinforcements in a proprietary process that ensures uniform dispersion, processability, and spec alignment.

Yes. We reverse-engineer and compound to meet OEM specifications, ASTM standards, or competitor benchmarks—including color, mechanical, and regulatory performance.

Absolutely. We develop and validate engineered compounds for FDA, ISO 13485, USP Class VI, and OEM automotive specs, including UV, chemical, and mechanical testing.

Yes. Americhem specializes in pre-colored and additive-integrated compounds that reduce steps and streamline processing, while maintaining critical performance properties.

Technical Data Sheets Library

Access datasheets for all compound lines, including InStruc®, InTherm™, ColorRx®, and more, to compare properties, compliance, and performance data.

Dig Deeper into Engineered Compound Applications

Built on 75+ years of materials innovation and the trusted legacy of LTL Color Compounders, our engineered compound solutions are supported by deep technical resources. Explore webinars, case studies, and technical downloads showcasing how Americhem’s custom compounds solve real-world design, processing, and compliance challenges.

Have a Question About Engineered Compounds?

Whether you’re designing the next breakthrough product or solving a legacy material challenge, our in-house team can guide your selection, formulation, and validation—fast.