- Products & Materials

-

-

-

Product Families

-

-

-

-

Products & Materials

We collaborate closely with your team to deliver application-specific plastic compounds and accelerate your time to market.

-

-

- Industries

-

-

Solutions for Your Industry

We work with manufacturers in high-stakes industries like healthcare, automotive, electronics and building materials where performance, compliance and reliability are essential.

-

- Building & ConstructionMaterials that withstand weather, UV, and structural demands in outdoor and load-bearing applications.

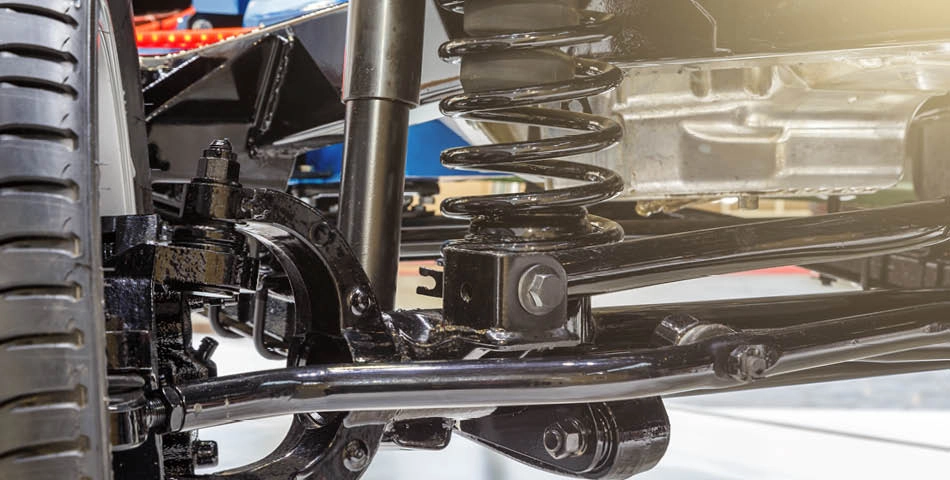

- TransportationEngineered compounds built for durability, compliance, and reliability across vehicles, aircraft, ag, and power sports.

- FibersSoftness, strength, and stability for nonwovens, synthetic turf, hygiene products, and performance textiles.

-

- PackagingCustom masterbatches and additives for barrier performance, clarity, and sustainable packaging formats.

- HealthcareMedical-grade materials engineered for biocompatibility, sterilization, and global regulatory compliance.

- ElectronicsFlame-retardant, antistatic, and heat-resistant compounds for electronic housings and sensitive components.

-

-

- Services & Expertise

-

-

Services & Expertise

Americhem isn’t just a compounder, we are a full-service extension of your engineering, marketing, and product development teams.

-

-

- About

-

-

About Americhem

For more than eight decades, Americham has been your trusted global partner in designing and manufacturing polymer solutions.

-

-

- Talk to an Expert

Choose, Customize, and Validate Faster

Select a base resin, then tune color, additives, and processing.

Americhem builds application ready materials by starting with the right base resin and layering color masterbatch, functional additives, and processing guidance to meet your targets for performance, appearance, and compliance.

- Polyolefins: PP, PE for lightweight, cost-efficient parts and capstocks

- Styrenics: ABS, ASA for toughness, paint-free color, and outdoor aesthetics

- Engineering: PC, PC/ABS, PA (nylons), PBT for strength, heat, and precision

- High-Performance: PSU/PESU/PPSU for sterilization, hot-water, and chemical resistance

- PVC & TPEs: Rigid/flexible PVC and soft-touch TPE/TPU for extrusion and overmolding

- Additives & Color: UV stabilization, FR, antimicrobial, ESD/EMI, lubricity, and special effects

Explore Material Versatility Across Resin Families

Discover the polymer platforms that power your products.

Every base material can be fine-tuned for mechanical, thermal, and surface performance, while hitting your regulatory and processing requirements. Explore common platforms below and how we customize them.

Explore Formulated Material Families

Jump into ready-to-customize platforms designed to solve common performance challenges.

Your Base Material Questions, Answered

Selection, customization, and validation – simplified.

We commonly work with PP/PE, ABS/ASA, PC/PC-ABS, PA, PBT, PVC, TPE/TPU, and PSU/PESU/PPSU, among others.

Yes, color masterbatch and functional additives (UV, FR, antimicrobial, ESD/EMI, lubricity, thermal) are integrated to meet your targets.

We support weathering, physical/thermal analysis, and documentation aligned to industry standards to de-risk scale-up.

Custom compounds, masterbatch, precolor, and dry-blend, matched to your process and cost goals.

Have a Question About Customizable Base Materials?

We can help you find the right base resin, troubleshoot processing, or recommend additive packages that meet your specs.