- Products & Materials

-

-

-

Product Families

-

-

-

-

Products & Materials

We collaborate closely with your team to deliver application-specific plastic compounds and accelerate your time to market.

-

-

- Industries

-

-

Solutions for Your Industry

We work with manufacturers in high-stakes industries like healthcare, automotive, electronics and building materials where performance, compliance and reliability are essential.

-

- Building & ConstructionMaterials that withstand weather, UV, and structural demands in outdoor and load-bearing applications.

- TransportationEngineered compounds built for durability, compliance, and reliability across vehicles, aircraft, ag, and power sports.

- FibersSoftness, strength, and stability for nonwovens, synthetic turf, hygiene products, and performance textiles.

-

- PackagingCustom masterbatches and additives for barrier performance, clarity, and sustainable packaging formats.

- HealthcareMedical-grade materials engineered for biocompatibility, sterilization, and global regulatory compliance.

- ElectronicsFlame-retardant, antistatic, and heat-resistant compounds for electronic housings and sensitive components.

-

-

- Services & Expertise

-

-

Services & Expertise

Americhem isn’t just a compounder, we are a full-service extension of your engineering, marketing, and product development teams.

-

-

- About

-

-

About Americhem

For more than eight decades, Americham has been your trusted global partner in designing and manufacturing polymer solutions.

-

-

- Talk to an Expert

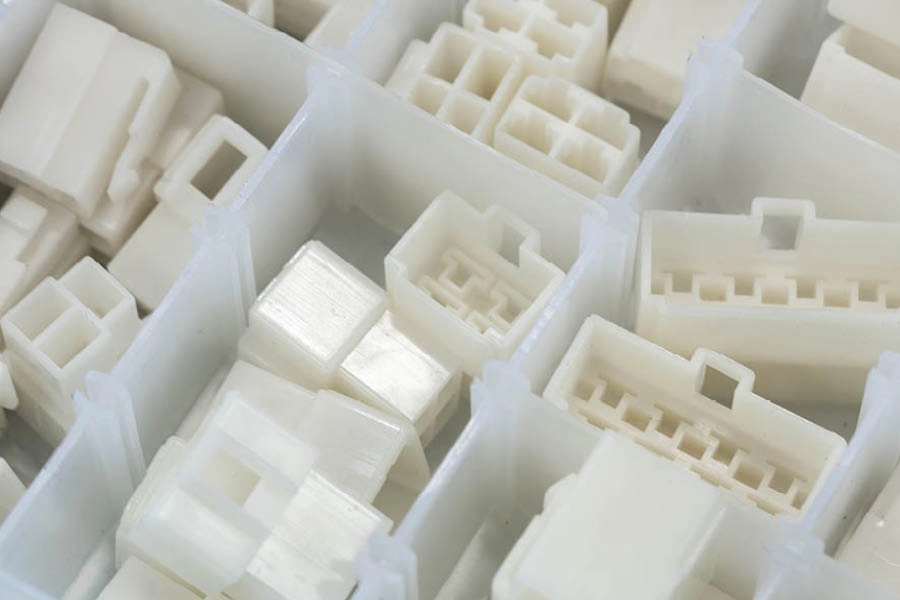

Compounds That Protect Analytical Integrity

Materials designed to preserve accuracy and extend equipment life.

Analytical equipment must perform with precision, repeatability, and reliability under challenging environments. Americhem develops engineered compounds that protect sensitive instruments while supporting manufacturing efficiency and cost control.

- Engineered resins and alloys tailored for test prep containers, gauges, and analyzers

- Reinforcements and additives that provide strength, toughness, and wear resistance

- Color-stable polymers for standardization across equipment lines

- Compounds that balance durability with compliance in industrial environments

Compounds That Solve Analytical Equipment Challenges

Engineered technologies that balance precision, durability, and compliance.

Build Analytical Equipment With Confidence

Americhem compounds are engineered to protect sensitive instruments, standardize quality, and extend product lifecycles, all while supporting efficient manufacturing.

Formulation Expertise That Safeguards Precision

From test prep containers to gas analyzers, Americhem ensures accuracy and durability.

The reliability of analytical equipment depends on the integrity of its polymer components. Americhem formulations are engineered to withstand chemicals, impacts, and environmental stresses while ensuring consistent performance.

Why analytical equipment manufacturers trust Americhem:

- Decades of experience compounding polymers for analytical devices and instrumentation

- Proven solutions for housings, trays, fluid contact parts, and moving components

- Reinforced, lubricated, and electrically active technologies that extend durability and safeguard performance

- Complete support from concept through production, with full regulatory documentation

Certified for Analytical Equipment Standards

Americhem analytical equipment compounds are developed under ISO 9001 quality systems and tested to meet stringent durability, flame retardancy, and ESD performance standards. Every batch is backed with documentation that ensures compliance in precision equipment markets.

Where Analytical Equipment Materials Are Made to Perform

Real materials. Real timelines. Real results. Partner with Americhem for analytical equipment compounds that deliver precision, compliance, and durability in testing instruments.