- Products & Materials

-

-

-

Product Families

-

-

-

-

Products & Materials

We collaborate closely with your team to deliver application-specific plastic compounds and accelerate your time to market.

-

-

- Industries

-

-

Solutions for Your Industry

We work with manufacturers in high-stakes industries like healthcare, automotive, electronics and building materials where performance, compliance and reliability are essential.

-

- Building & ConstructionMaterials that withstand weather, UV, and structural demands in outdoor and load-bearing applications.

- TransportationEngineered compounds built for durability, compliance, and reliability across vehicles, aircraft, ag, and power sports.

- FibersSoftness, strength, and stability for nonwovens, synthetic turf, hygiene products, and performance textiles.

-

- PackagingCustom masterbatches and additives for barrier performance, clarity, and sustainable packaging formats.

- HealthcareMedical-grade materials engineered for biocompatibility, sterilization, and global regulatory compliance.

- ElectronicsFlame-retardant, antistatic, and heat-resistant compounds for electronic housings and sensitive components.

-

-

- Services & Expertise

-

-

Services & Expertise

Americhem isn’t just a compounder, we are a full-service extension of your engineering, marketing, and product development teams.

-

-

- About

-

-

About Americhem

For more than eight decades, Americham has been your trusted global partner in designing and manufacturing polymer solutions.

-

-

- Talk to an Expert

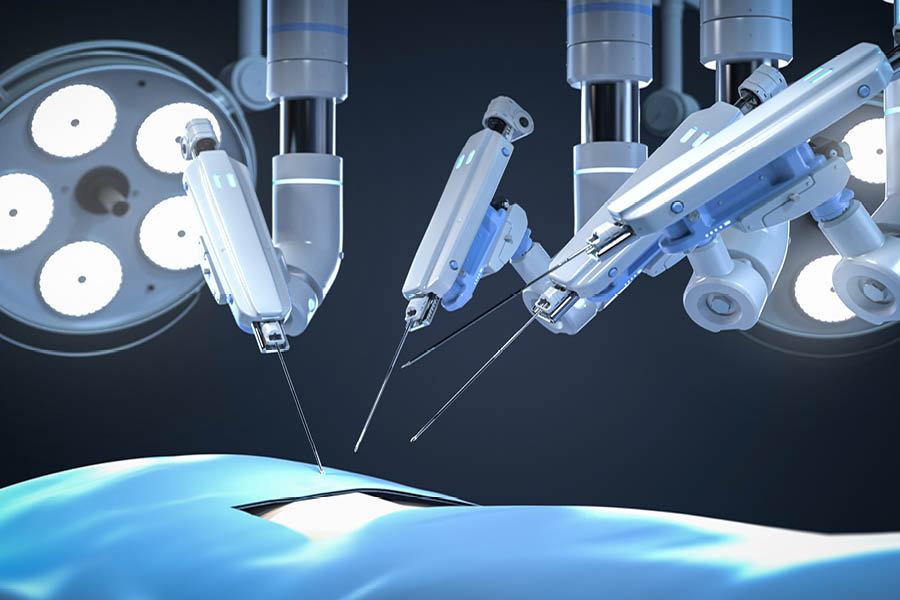

Designed for High-Stakes Healthcare & Medical Device Applications

From surgical devices to home health and consumer products, Americhem partners with OEMs and manufacturers across the healthcare spectrum to deliver proven, medical-grade polymer compounding expertise. Our formulations are engineered for performance, compliance, and reliability, helping you accelerate timelines, reduce risk, and get products to market faster.

We help you:

- Accelerate development timelines with first-time-right material performance

- Meet stringent regulatory and biocompatibility standards

- Reduce sourcing delays with proven, compliant formulations

- Back every material with technical data and global market support

- Supply materials trusted in FDA Class II and globally regulated devices

Smart Solutions for Every Healthcare Market Segment

From operating rooms to home healthcare, Americhem delivers custom medical-grade colorants and polymer compounds that meet the industry’s most demanding performance, regulatory, and aesthetic standards. Our materials are engineered to enhance safety, longevity, and brand differentiation, helping your products succeed in high-stakes healthcare environments.

Custom-Engineered Healthcare Materials, Proven in Performance

Get precision-engineered medical-grade compounds, healthcare polymers, and flame-retardant solutions backed by hands-on support and data-driven performance testing.

Medical Grade Polymer Compounding Built for Product Engineers

You need materials that support faster prototyping, lower development risk, and long-term product success. Our medical grade polymers are engineered for performance in real clinical environments and supported by compliance data from the start.

- Biocompatible plastics tested to ISO 10993-5 for regulatory approval

- Built to withstand repeated sterilization and chemical exposure

- Antimicrobial options available for surgical tools and diagnostic housings

- Moldable compounds that support complex designs and consistent production

Get regulatory-grade compounds trusted by medical device manufacturers worldwide.

Trusted by Healthcare OEMs. Proven to Deliver.

We deliver materials for the health and wellness industry that meet FDA requirements, biocompatible standards, and strict performance specs. You get hands-on support for formulation, documentation, and validation, backed by a compounder trusted where failure isn’t an option.

Where Healthcare Materials Are Made to Perform

Real materials. Real timelines. Real results. Partner with a team known for technical expertise, consistent quality, and customized solutions that perform in the real world.