Soft-Touch Performance

Ideal for grips, handles, tubing, and wearable parts thanks to rubber-like feel and stretchability.

Americhem’s thermoplastic elastomers blend softness, strength, and clean processing. Each compound is tuned to your specific tooling, compliance, and material needs.

Americhem custom formulates thermoplastic elastomers across a range of SBC, TPV, and TPO chemistries. We fine-tune each compound to your required hardness while dialing in flow, color compatibility, and regulatory readiness.

Applications include:

Built for injection and extrusion, and compatible with blow molding, compression, and overmolding. Offered in recyclable and bio-based formats to meet material circularity or regulatory demands. Validated in our in-house labs. Proven across industries.

Whether your spec calls for ergonomic comfort, compliance, or high-output processing, Americhem’s TPEs are custom-compounded and lab-validated for real-world use.

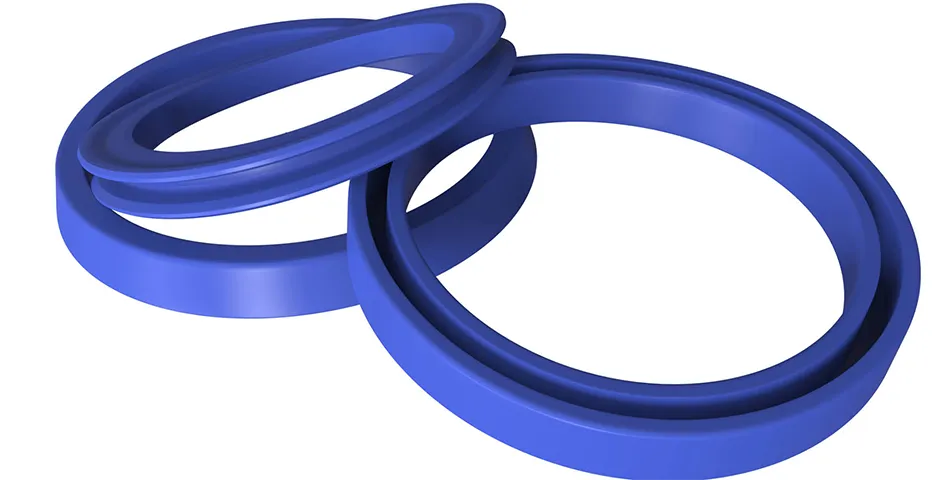

Americhem’s thermoplastic elastomers deliver comfort, sealing integrity, and consistent performance. Each TPE is tailored to your part design, equipment, and end-use requirements—then verified in our in-house labs.

Ideal for grips, handles, tubing, and wearable parts thanks to rubber-like feel and stretchability.

Designed for injection molding and extrusion, also compatible with blow and compression molding. Validated across production scenarios for consistent output.

Consistent sealing for closures and tubing, with reliable recovery and performance.

Formulated to meet medical, food contact, and global regulatory standards.

Each compound line is engineered for specific performance; whether it’s soft-touch feel, chemical resistance, or structural elasticity.

UV, chemical, and softness for our automotive interior part. The precoloring matched our OEM target and helped us skip a secondary process.”

From compliance questions to processing fit, here are the most common questions teams ask when specifying Americhem’s thermoplastic elastomers.

Still have questions?

TPEs are thermoplastic elastomers that combine rubber-like softness with melt-processability. Unlike thermoset rubber, TPEs aren’t cross-linked, so they can be reprocessed, recycled, and remolded.

Yes. We formulate TPEs across the full Shore A to Shore D range, with dialed-in color dispersion, tactile feel, and additive effects like antimicrobial or lubrication.

Our TPEs are designed for injection molding and extrusion, and are compatible with blow molding, compression, and overmolding—including co-extrusion and insert molding.

Absolutely. Americhem offers TPEs that meet FDA, REACH, RoHS, NSF/ANSI 51, and toy safety standards—with documentation to streamline your compliance process.

Dive into whitepapers, case studies, and brochures that show how Americhem’s TPEs perform in real-world applications.

Whether you’re navigating regulatory hurdles, tuning softness, or validating material performance, our team can help you spec the right TPE fast.