Electrical Conductivity

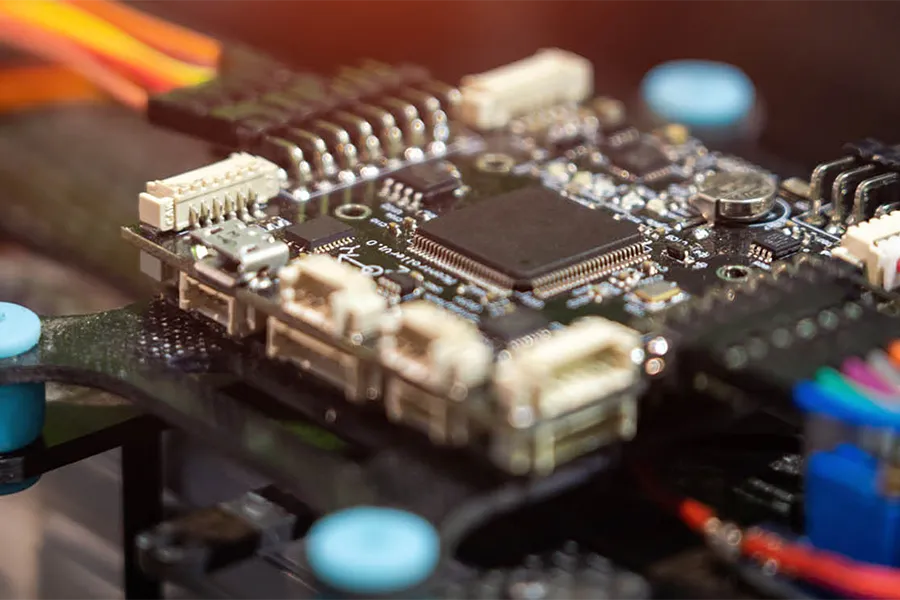

Enables EMI shielding, ESD performance, and signal control.

Americhem’s carbon fiber additives deliver dual functionality: structural reinforcement and electrical performance. Whether it’s housings that require EMI shielding or components that must hold tolerance under load, our compounds go beyond filler to improve both strength and signal control.

Available as masterbatch, compound, or custom blend, these materials integrate with engineering thermoplastics like PA, PC, PEEK, and PPS. Each formulation is tailored to your mechanical, thermal, and electrical targets, helping you reduce weight, replace metal, and meet regulated performance demands.

Ideal for electronics packaging, EV parts, and ESD-safe equipment requiring dissipative or conductive behavior.

Carbon fiber improves strength-to-weight ratio while enabling static or EMI protection.

Americhem carbon fiber polymer technologies are engineered for real-world manufacturing performance. From shielding electronics to reducing part weight and wear, Americhem helps OEMs turn performance demands into manufacturing-ready solutions. Conductive or dissipative, we’ll tailor the compound to meet your specs.

Enables EMI shielding, ESD performance, and signal control.

Maintains tolerance and rigidity under thermal or mechanical stress.

Ideal for metal replacement in automotive and aerospace parts.

Formulated for extrusion, injection molding, or film applications.

We can help you select the right formulation, troubleshoot conductivity targets, or meet your reinforcement goals.