Structural & Dimensional Stability

Rigid and semi-rigid PVC compounds built to hold shape under stress, retain gloss, and maintain tolerances in profile or load-bearing applications.

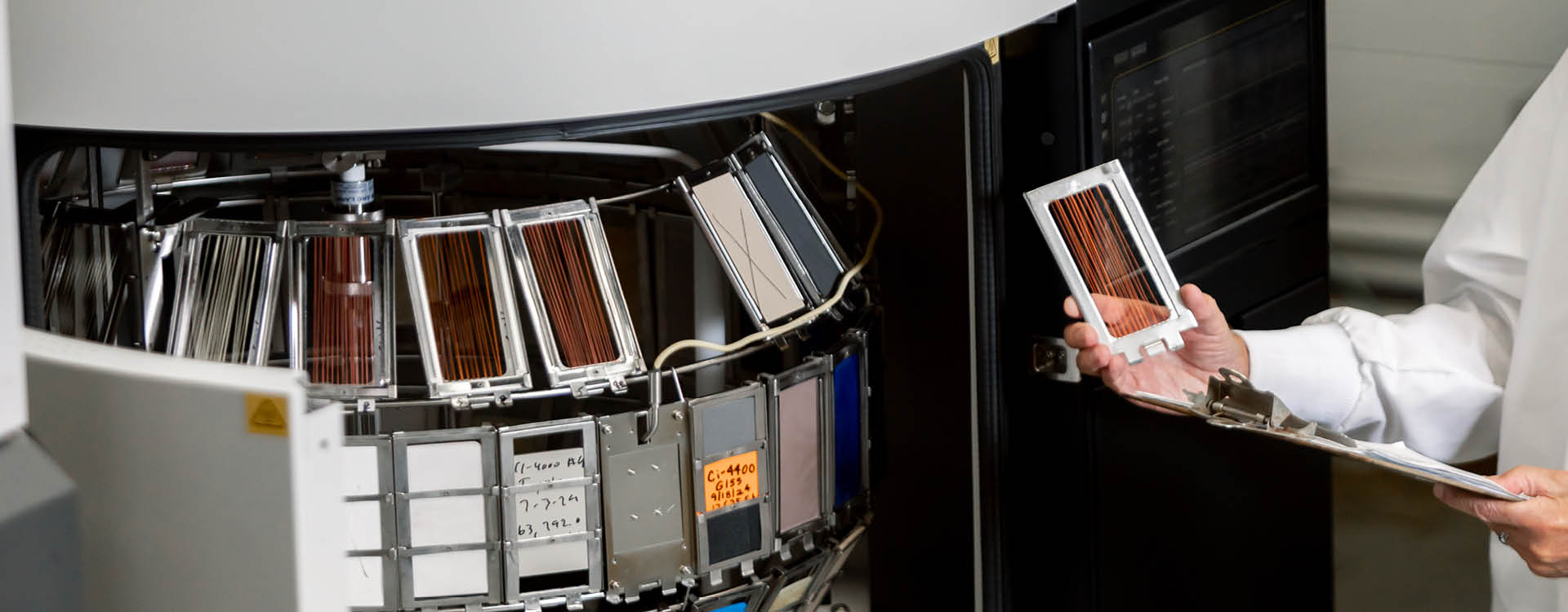

Americhem designs rigid and flexible PVC compounds to meet the specific mechanical, aesthetic, and processing requirements of each application. Our compounds support extrusion, molding, and co-extrusion processes with consistent flow behavior, surface finish control, and additive compatibility.

We develop each formulation with end-use conditions in mind, whether that means exposure to UV and moisture, chemical contact, or impact over time. Color is integrated from the start, reducing secondary operations and improving production efficiency.

Applications include:

Each Americhem PVC compound is tested in-house for performance, consistency, and appearance so your product reaches market faster and lasts longer.

Whether you’re engineering a capstock, molding a rigid profile, or dialing in color on a flexible wrap, Americhem PVCs are formulated to meet exacting requirements with minimal reformulation downstream.

Americhem’s PVC compounds deliver structural integrity, color stability, and manufacturing consistency across extrusion, molding, and co-extrusion environments. Built for real-world performance and validated in-house.

Rigid and semi-rigid PVC compounds built to hold shape under stress, retain gloss, and maintain tolerances in profile or load-bearing applications.

Formulations designed to reduce whitening, resist surface damage, and retain gloss, especially in high-visibility or dark-color profiles.

Fire-rated PVCs that meet Class A, WUI, or other code requirements while preserving appearance and flow during processing.

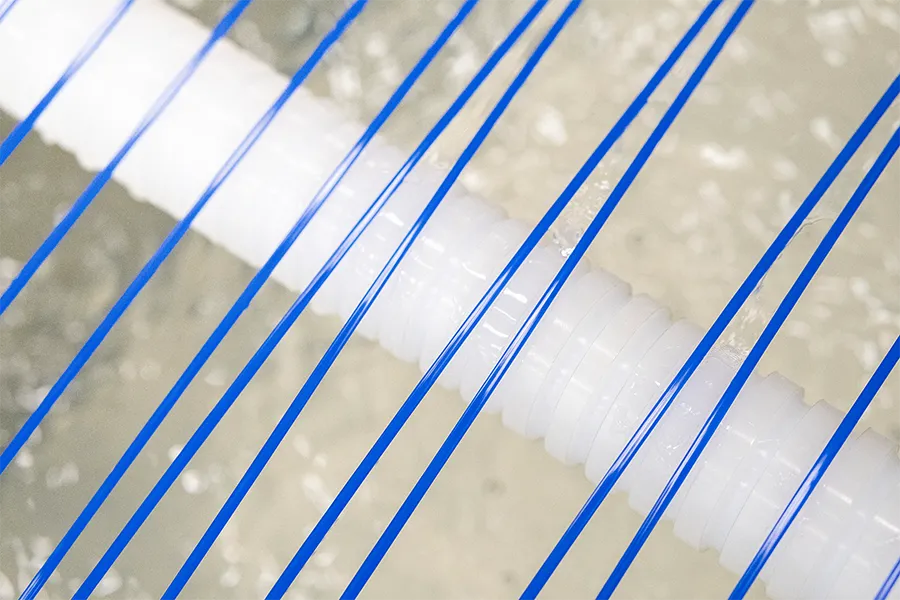

Flexible PVC blends for trims, wraps, and seals, compatible with coextruded profiles and tuned for softness, toughness, and recovery.

Precolored compounds with gloss control, texture integration, and nGrain® simulation for realistic, fade-resistant woodgrain designs.

Single-additive systems and masterbatch colorants that improve UV resistance, flow, and processing throughput.

Americhem’s PVC portfolio includes rigid, flexible, and weatherable compounds, each engineered to deliver performance, compliance, and aesthetic precision across manufacturing environments. Browse by formulation type to find the compound that fits your part design, processing method, and end-use environment.

Whether you’re specifying fire-rated profiles, dialing in dark-color gloss, or coextruding with flexible wraps, here’s what engineering and sourcing teams ask most.

Still have questions?

Rigid PVC (uPVC) is unplasticized, offering higher stiffness, UV durability, and structural stability, ideal for capstocks, trims, and profiles. Flexible PVC includes plasticizers, giving it softness and elasticity for seals, wraps, and soft-touch applications.

Yes. We offer precolor, dry blend, and masterbatch systems designed for brand alignment, colorfastness, and gloss control, plus woodgrain surface effects via nGrain® technology.

Our dark-color EPVC compounds are engineered for moisture whitening resistance, reduced heat build, and long-term color retention, even in UV-exposed applications like siding and trim.

Absolutely. We formulate for strong interlayer bonding, color and gloss consistency, and processing compatibility across rigid, flexible, ASA, and HDPE layers, validated in real extrusion environments.

We can help you spec the right formulation, align color and gloss targets, or troubleshoot a coextrusion or processing challenge fast.