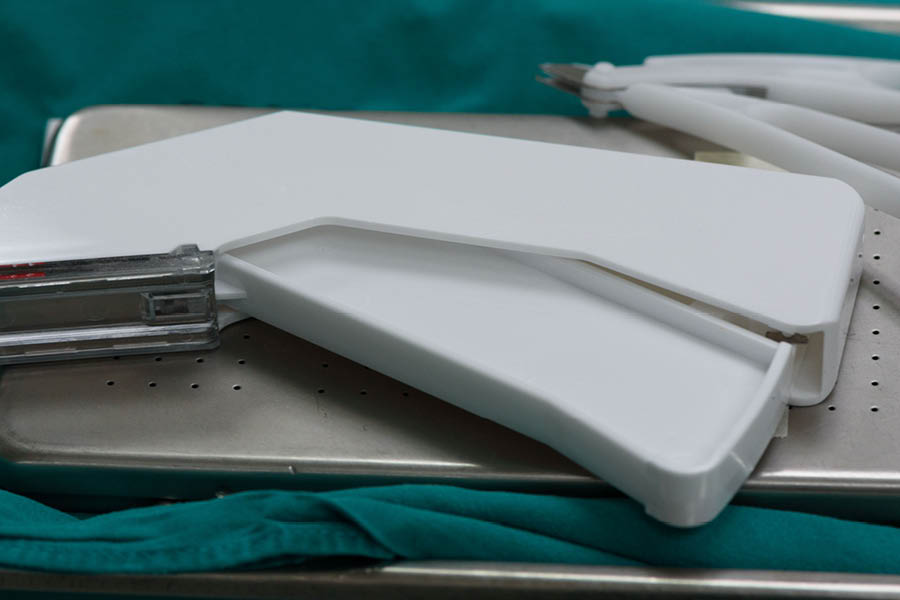

Endo Staplers

Withstand force and movement with rigid, durable materials that offer precision under pressure.

Americhem’s custom polymer compounds for surgical devices are formulated to meet the strictest performance and regulatory standards in the healthcare industry.

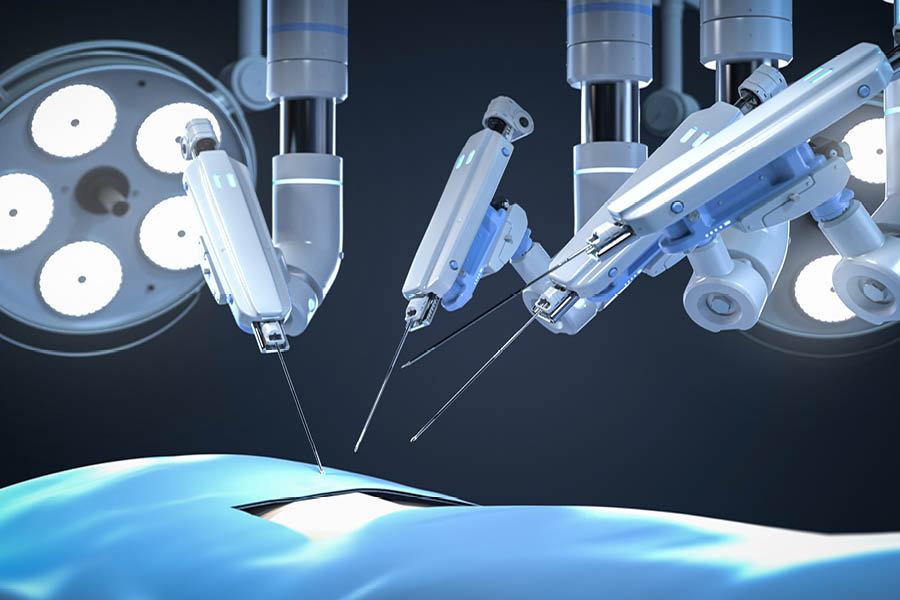

From site access to endo staplers and robotics, our medical-grade polymers support complex designs and sterilization methods.

Every device category has unique material challenges. We help you solve them.

From endo staplers to robotic instruments and women’s health devices, Americhem provides biocompatible colorants and medical-grade additives engineered to meet regulatory and performance demands. Our solutions are ISO 10993-5 and USP Class VI compliant, and are customized to enhance visual identification, durability, and sterilization resistance.

Withstand force and movement with rigid, durable materials that offer precision under pressure.

Formulated for stability, repeatability, and custom color coding in surgical robotic components.

Designed for lubricity, strength, and barrier properties in surgical access ports and sheaths.

Color-stable, wear-resistant polymers for diagnostic tools and handheld dental equipment.

Biocompatible, comfortable, and resilient materials tailored to Class II and lifestyle-focused products.

Choose Americhem as your surgical device material partner to accelerate validation and hit your launch deadlines.

With decades of expertise, Americhem supports OEMs with materials tailored to their performance, regulatory, and design goals.

Americhem compounds for surgical applications are designed to meet ISO 10993-5, FDA 21 CFR, and USP Class VI requirements, giving you speed and confidence through regulatory review.

Explore Certifications

Real materials. Real timelines. Real results. Partner with Americhem for proven performance, every step of the way.

Request a Custom Solution